Solidworks

- Overview

- Modules

- Benefits of getting training with LCT

- Course Outcome

- Certification Sample

- Student's project

Overview:

SolidWorks is a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) computer program. SolidWorks currently markets several versions of the SolidWorks CAD software in addition to eDrawings, a collaboration tool, and Draft Sight, a 2D CAD product.

Objective:

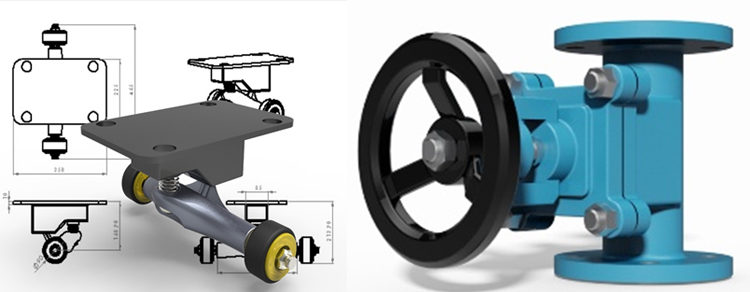

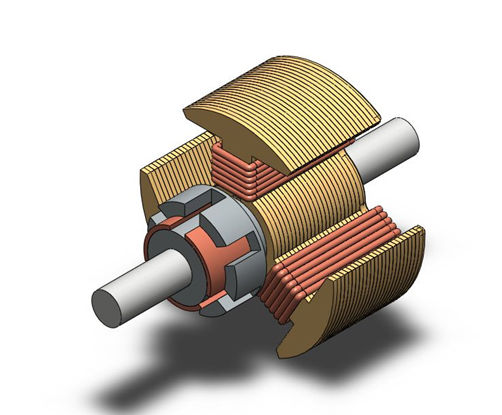

3D solid modeling is a critical aspect for modern product development and provides the basis for design, simulation, and manufacturing of any part and assembly across a broad range of industries, applications, and products.

Pre-requisite:

Entire program carries modelling and other design applications. Students pursuing diploma and degree programs in mechanical, automobile and aeronautical can enroll in this program.

Duration:

75 Hours.- Sketching Tools

- Editing Tools

- Adding dimensions & Relations

- Blocks concept - Creating& Inserting blocks

- Extrude features, Revolve features

- Hole and its types

- Fillet, Chamfer, Shell, Rib

- Draft, Mirror features, Wrap

- Pattern and its types

- Swept features, Loft features

- Boundary boss feature, Reference Geometries

- Inserting curves

- Inserting Planar Surface, Offset Surface, Radiate Surface

- Extend surface, Surface fill, Ruled Surface

- Trimming Surface, Mid surface, Knit surface

- Replace Face, Delete face, Untrim surface

- Freeform, Thicken, Thicken cut, Cut with Surface

- Inserting and Creating components, Move and Rotate components

- Applying Standard Mates

- Applying Mechanical Mates, Applying Smart mates

- Assembly design practice

- Pattern components

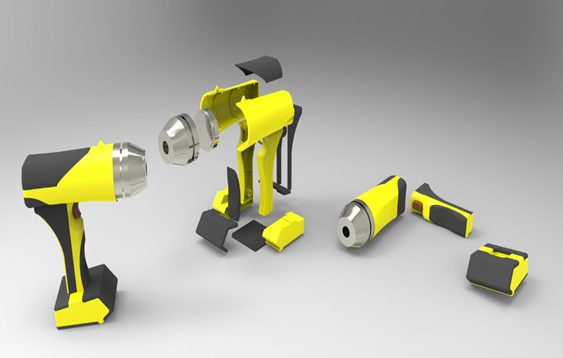

- Creating exploded views, Top down approach

- Creating user defined profile for structural member, Inserting Structural Member

- Inserting Gusset, Fillet Bead, End cap, Mirror

- Extruded Bose/Base, Trim/Extend, Placing Holes, Cut List

- Base Flange/Tab, Edge Flange

- Conversion of Solid Body To Sheet Metal, Miter Flange, Swept Flange

- Jog, Hem, Corners

- Rip, Sketched Bend, Fold/Unfold

- Cross Break, Lofted Bend, Flatten

- Forming Tools, Inserting Sheet Metal Gusset

- Adding Corner Trim, Lofted Trim, Bend Table

- Generating Views (Projection, Sectional & Detailed, Auxiliary & Break out views)

- Creating Dimensions, Creating GD&T Symbols On Drawings

- Creating Balloons, Bill Of Materials

Sketcher tools:

Part & Surface Modeling:

Assembly Modeling:

Weldments:

Sheet metal design:

Generative Drawing Views:

Benefits of getting training with LCT

- Learning from certified instructors.

- Program will be carried on both student and industrial basis.

- Certification from cadd technologies school design private limited.

- Students will be offered with worthy work book

Course Outcome

- Student will learn to sketch with accurate dimensions and study engineering drawings.

- Student will understand 3D views and make 3D models with accurate specifications and features.

- Student will create assembly components by understanding constraints and GD&T concepts.

- Student will learn to produce industry drawings for their productive models.

- Student will be innovative and get updated in their technical skills and will be capable of facing interviews.