- Overview

- Modules

- Benefits of getting training with LCT

- Course Outcome

- Certification Sample

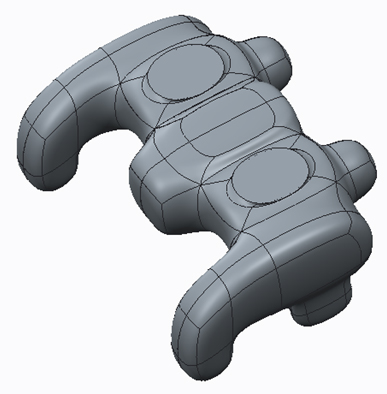

- Student's project

Overview:

Industrial designers understand just how much looks matter. That's why they work to make their creations stand out on the shelf or in the showroom. Complex curves, the smoothest of high-quality surfaces, compelling product renderings. Use the freestyle design capabilities to do rapid freeform surface creation and attach surfaces to your parametric model.

Objective:

Surfaces and curves can instantly adapt to design changes, reducing product development time.

Build free-form geometry at any point in the design, using as many or as few constraints as desired, for maximum design flexibility.

Full control over the degree and multiplicity of the surface, Manipulate surfaces faster with direct surface editing and directly edit and control the surface math with multi resolution control point editing.

Pre-requisite:

Entire program carries modeling and other design applications. Students pursuing diploma and degree programs in Mechanical, Automobile and Aeronautical can enroll this program.

Duration:

120 Hours.- Introduction & Understanding to Creo Parametric Concepts

- Using Creo Parametric Interface

- Selecting of Geometry, Features, Models

- Editing of Geometry, Features, Models

- Sketcher Theory, Design Intent & Constraints

- Lines, Rectangles, Circles, Arcs, Ellipse

- Spline, Fillet, Chamfer, Text, Offset, Thicken, Palette

- Construction Geometry Theory, Geometry Tools

- Dimensioning Entities, Modifying Dimensions

- Sketch Feature, Sketch Setup, Sketch References, Entity from Edge

- Datum Features Theory, axes and planes

- Creating Extrudes

- Revolves, Ribs

- Creating Holes,

- Shells, Draft

- Creating Patterns

- Creating Rounds, Chamfers

- Using Layers

- Assembly & Constraint Theory, Default, Coincident Constraints

- Distance, Parallel, Normal, Angle, Automatic Constraints

- Exploding, Replacing Components

- Cross-Sections & Display Styles in Assemblies

- Advanced Selection, Creating Sweeps

- Blends, Rotational Blends

- Sweeps with Variable Sections

- Helical Sweeps

- Swept Blends

- Relations, Parameters

- Family Tables, Groups

- Copy, Mirror

- UDF

- Measuring, Inspecting Models & Seeking Help

- Capturing, Managing Design Intent

- Resolving Failures

- Introduction to Flexible Modeling

- Editing, Transformations

- Recognition in Flexible Modeling

- Component Interfaces

- Flexible Components, Restructuring

- Simplified Reps, Assembly Structure

- Skeletons, Copying model, Multiple Skeletons

- Sharing Skeleton Geometry, Creating and Placing Models

- Sheet metal Design Process

- Fundamentals, Creating Primary Wall Features

- Secondary Sheet metal Wall Features, Relief

- Bending, Transition To Bends

- Unbending, Bend Back, Flat States, Cuts

- Die Form, Punch Form, Rip Features

- Drawing Concepts, Ribbon, Formats, Sheets, General & Projection Views

- Editing Views, View Area, Detailed, Sectioned, Exploded Views

- Adding Model Details to Drawings

- Tolerance Information to Drawings

- Adding Notes, Symbols, Tables

- Report Tables, BOM Balloons

- Layers in Drawings, Drawing Environment

- Advanced Datum Features

- Basic & Boundary Blend Surfaces

- Surface Analysis Tools

- Extending, Trimming & Manipulating Surfaces

- Creating & Editing Solid Using Quilts

- Introduction & Understanding Free Form Surface Modeling Concepts

- Creating Curves & Developing Surfaces in Free Form Surface Modeling

- Introduction to Creo Direct & Creating Sketches in 2-D Mode

- Creating Features & Assemblies in Creo Direct

- Selecting, Modifying & Reusing 3-D Geometry in Creo-Direct

ATC's Part (Basic) & Assembly Modeling (Basic) - Creo:

ATC's Part (Adv) & Flexible Modeling - Creo:

ATC's Assembly (Adv), Sheet metal Modeling & Detailing - Creo:

ATC's Surface Design & Direct Modeling - Creo:

Benefits of getting training with LCT

- Learning from a PTC Certified Instructor.

- Exposure to PTC training methodology & curriculum.

- Studying the finest practices and applications .

- Student name gets reflected on PTC website on course completion

- Each student will receive Personal Creo 2.0 Student version license software.

- PTC course material has been provide to the individuals.

Course Outcome

- Student will learn to sketch with accurate dimensions and study engineering drawings.

- Student will understand 3D views and make 3D models with accurate specifications and features.

- Student will create assembly components by understanding constraints and GD&T concepts.

- Student will learn to produce industry drawings for their productive models.

- Student will be innovative and get updated in their technical skills and will be capable of facing interviews.